新闻中心/ News

2021年12月简报-December 2021 Newsletter

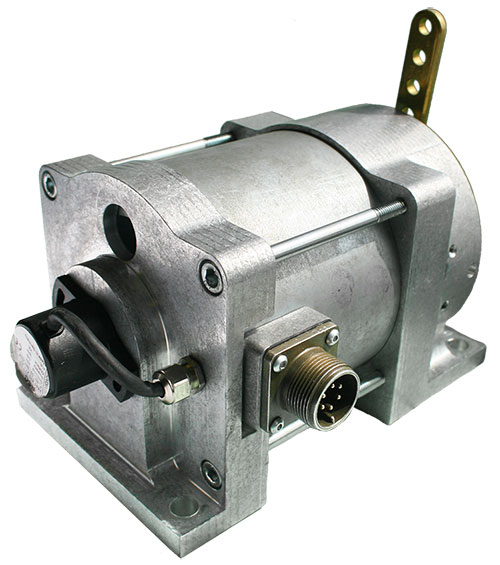

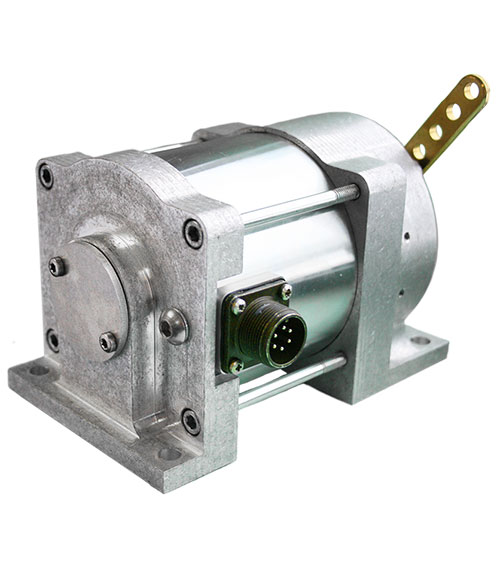

Product of the Month: ADB335 Series Actuator

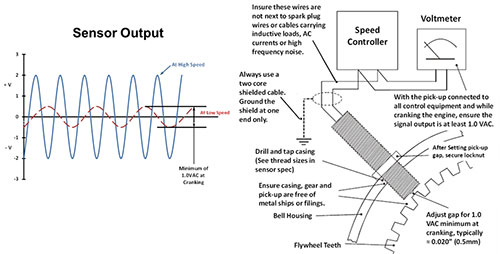

The universal electric actuator is a rotary output, proportional servo. Easy to install, built with precision bearings and no maintenance required, this electromechanical actuator is typically used for mechanical actuation of fuel system control levers for diesel and gaseous fueled engines. An internal spring provides fail safe operation by forcing the actuator to the fuel shut off position when the actuator is de-energized. The design combines rapid transient response with a wide rotational angle for extended linear travel and proven reliability in the field.

- 24 V DC

- 3.3 lbf.ft (4.5 N m) Net Torque

- 65° Shaft Rotation

- Die-Cast Housing

- Military Style Connector

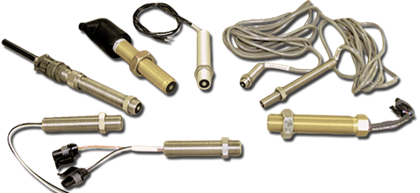

- Available Options:

- Position Feedback Sensor

- Mating Connectors, Straight and 90°

- 12' (3658 mm) Cable Harness Assemblies with Straight or 90° Connectors

- Mounting - Vibration Dampeners

Application of the Month

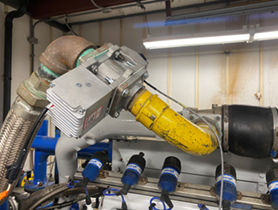

BioWorks Energy LLC of Grand Blanc, MI built a custom biogas fueled co-generation unit using a 21.9L, V12 MAN E2842 engine. Cogeneration (cogen) through combined heat and power is the simultaneous production of electricity with the recovery and utilization of heat.

Cogeneration is a highly efficient form of energy conversion and achieves a primary energy savings of approximately 40% compared to the separate purchase of electricity from a utility company’s electrical grid and a separate gas boiler for onsite heating.

Cogeneration is a highly efficient form of energy conversion and achieves a primary energy savings of approximately 40% compared to the separate purchase of electricity from a utility company’s electrical grid and a separate gas boiler for onsite heating.

ATB552T2F14-24 INTEGRATED ACTUATOR/THROTTLE BODY

Gaseous fueled cogen units are typically used for commercial, residential, and industrial applications and can easily be configured with a GAC ATB (integrated actuator/throttle body assembly) controlled by a variety of digital or analog governors with an ‘Anti-Wind-Up’ PID feature that minimizes RPM over-shoot and/or under-shoot. The ‘Anti-Wind-Up’ PID is specifically designed for gaseous fueled engines

Gaseous fueled cogen units are typically used for commercial, residential, and industrial applications and can easily be configured with a GAC ATB (integrated actuator/throttle body assembly) controlled by a variety of digital or analog governors with an ‘Anti-Wind-Up’ PID feature that minimizes RPM over-shoot and/or under-shoot. The ‘Anti-Wind-Up’ PID is specifically designed for gaseous fueled engines

|

|

|

|||||||||||||